Fabrics

Manufacturer process(baseball cap manufacturing)-Most fabrics used for caps are made 100% cotton. A twill construction is most commonly used and the fabrics are coming in a great variety of constructions. However, polyester, acrylic, wool as well as mixes of these yarns are also used. All fabrics have been re-active dyed to avoid color bleeding.

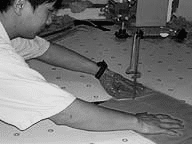

Cutting of fabrics

The fabric will be placed on the cutting table in layers and markers made for each hat panel will be placed on top of the fabric pile. The top fabric layer is marked and the fabrics are then cut by a handheld or fixed electric saw. There might be very slight variations in the dyeing lots.

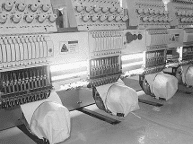

Decoration

Decoration of hats and caps, being embroidery, printing or badges should take place before the hat is fully constructed. For embroidery, we used new Tajima embroidery machines, for printing is silk screen printing using imported inks and badges are made by factories using Taiwanese technology and equipment.

Assembling

The decorated panels will be passed to the sewing lines for stitching the panels and peak together and generally assemble the hat with sweatband, strap/closing, top button and sewn-on labels.

There are a great variety of closings to choose from, like velcro, plastic snaps, zippers and metal buckles.

Quality control

The hat are passed to the finishing section where the loose sewing threads will be cut off and the quality control section will inspect the finished products. Upon completion, the hats will be shaped by using a hot mould then packed.